-

Tel :+86 592 5159077

-

Email : [email protected]

The Importance of Dimensional Stability in Uniform Fabric Orders

May 15, 2024Workwear and uniforms serve a vital role in various industries, ranging from hospitality to manufacturing, where durability and functionality are paramount. However, one often overlooked yet crucial aspect of these garments is dimensional stability in the fabric used. Dimensional stability refers to the ability of fabric to maintain its original shape and size despite repeated laundering and wear.

Imagine a workforce clad in ill-fitting uniforms that have shrunk or stretched after a few washes. Such garments not only compromise the professional image of the organization but also affect the morale and confidence of the employees. Dimensionally stable fabrics maintain the integrity of the uniform's design, ensuring a consistent and polished appearance over time. Fabrics with excellent dimensional stability can prolong the lifespan of garments. Fabrics that resist shrinking or stretching maintain their shape and size, reducing the need for frequent replacements. To conclude, dimensional stability plays a vital role in ensuring professional appearance of workwear uniforms.

What factors influence shrinkage?

1. Different raw materials in fabrics lead to different shrinkage rates. Generally, fibers with high moisture absorption will swell in water, increasing in diameter and shortening in length, resulting in higher shrinkage. For example, some viscose fibers have a water absorption rate of up to 13%, whereas synthetic fiber fabrics have poor moisture absorption and therefore have lower shrinkage rates.

2. The density of the fabric also affects shrinkage. If the warp and weft densities are similar, the shrinkage rates in the warp and weft directions will also be similar. Fabrics with a higher warp density will shrink more in the warp direction, whereas fabrics with a higher weft density than warp density will shrink more in the weft direction.

3. The thickness of the yarn in the fabric affects the shrinkage rate. Fabrics made with thicker yarns will have higher shrinkage rates, while those made with finer yarns will have lower shrinkage rates.

4. Different production processes result in different shrinkage rates. Generally, during the weaving and dyeing processes, fibers undergo multiple stretches. Fabrics that are processed for longer durations and subjected to greater tension will have higher shrinkage rates, and vice versa.

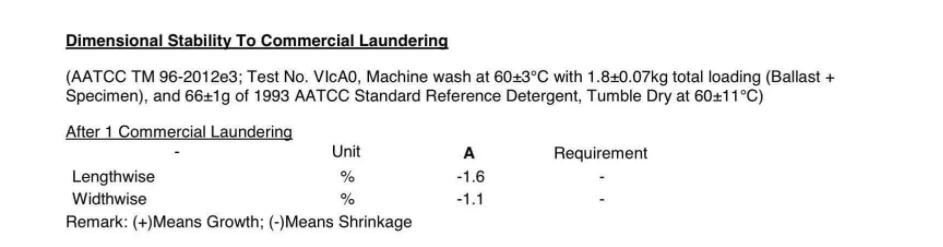

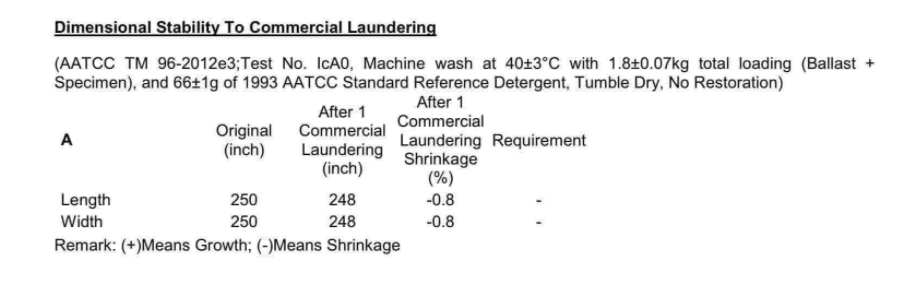

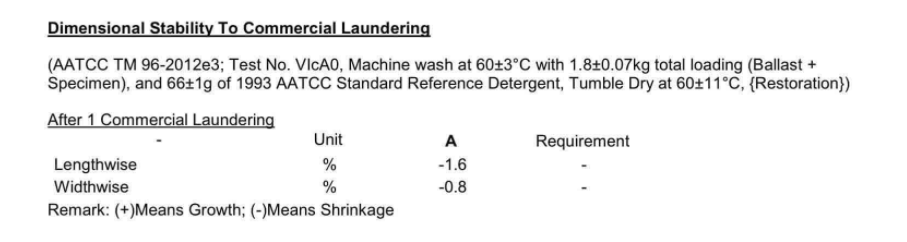

Returning to our products, overall, the shrinkage rates of the workwear and uniform fabrics we produce are quite satisfactory. For instance, the shrinkage rate of our polyester wool blended fabrics and polyester cotton fabrics is typically controlled within ±2%. For nylon cotton blend fabrics, the shrinkage rate is controlled within ±3%, and for pure cotton fabrics, it is controlled within ±3.5%. Our technicians have thoroughly considered every aspect, including fabric composition, yarn configuration, and production processes, to achieve the best possible shrinkage performance.

Welcome Your Inquiry To Us

Mob/Whatsapp : +86 15959213137

Tel : +86 592 5159077

Email :

[email protected]

Skype : +86 15959213137

21F, No. 295, Jiahe Road, Xiamen, China.

Get A Free Quote